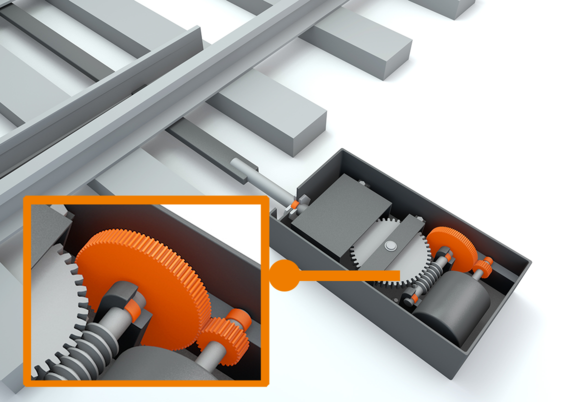

Rail technology: maintenance-free polymer gears support track switching

To reduce interruptions of rail journeys, track switches are used. They ensure the seamless transition of the rail vehicles from one track to another. Reliable track switches are fundamental for a smooth operation of passenger and freight transport.

Using our wear-resistant iglidur® I3 gears contributes to a long service life of the application.

Using our wear-resistant iglidur® I3 gears contributes to a long service life of the application.

- What was needed: iglidur® I3 gears

- Requirements: the track switches are exposed to harsh environmental conditions, such as dirt, moisture and temperature fluctuations. Therefore, the gears have to be extremely robust.

- Industry: railway technology

- Success for the customer: iglidur® I3 gears are robust, wear-resistant, corrosion-free, light and lubrication-free. They are also very insensitive to dust and dirt and easily absorb shocks and impacts.

The challenge

The metal gears used there require external lubricants. This makes regular maintenance necessary, which costs a lot of time and money. Furthermore, omission of the lubricant can lead to failures.Solution

With gears printed in 3D from iglidur I3, downtime is reduced, as they have good emergency running properties and can be used without external lubricants. A further advantage of the iglidur gears is their resistance to corrosion.In addition, replacement parts printed in 3D at igus are available within one to three days, with no minimum order quantity.