Clean, resilient and maintenance-free: bearings in sausage cutting machines

Lubrication and maintenance-free polymer bearings work in continuous operation in sausage cutting machines

On the one hand, the highest priority for machines in food production is their robustness; on the other, they must be easy to clean. To ensure that germs have no chance at all, very strong cleaning agents and lots of water are usually used. They must not have any influence on machine availability in the long term. In this aggressive environment lubrication-free polymer plain bearings prove themselves, which reliably and permanently withstand all adversities.Profile

- What was needed: iglidur plain bearing, igubal spherical bearing, drylin linear technology

- Requirements: All components must must be usable in combination with stainless steel and be lubrication-free. They work at least five days a week, with three shifts in each case. All interior and exterior areas must also be able to withstand wet conditions and cleaning chemicals.

- Industry: Food industry

- Success for the customer: The machine manufacturer relies on maintenance-free and lubrication-free polymer plain and spherical bearings and linear technology from igus in its entire range of machines and systems. They are economical, easy to install and harmonise with stainless steel.

Problem

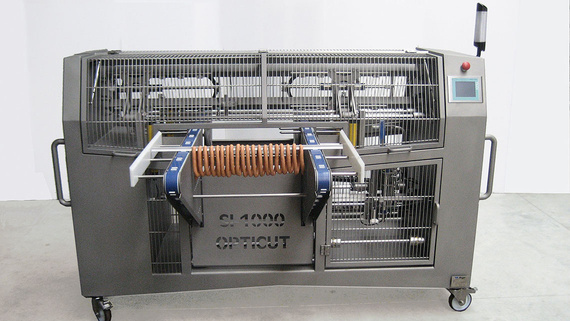

The company Singer & Sohn GmbH is active in special machine construction, primarily in the food and beverage industry. It often happens that the machines are used in sausage and meat production.This is also the case with the ′OptiCUT SI-1000′ sausage link cutting machine. Whereas the employees used to slice the sausage by hand, the machine now performs this task. Among other things, it is more hygienic, more precise and faster than would be possible by hand. A camera system optically detects the linking points and ensures the positioning of the knives. The sausages are first fixed inside the machine, then spread and finally each separated at the bottom.

The Singer & Sohn machine range is characterised by being exceptionally reliable, durable and robust. Because in the highly competitive market, under no circumstances should unnecessary service and maintenance times be incurred. In addition, the customised machines are always made entirely of stainless steel. The material guarantees durable and hygienic operation, and so all other machine elements must also be matched to the material.

In addition, it is always important to consider the absence of lubricants in the machine components. For example, lubricants are taboo in food production, the risk of product contamination is far too great.

But there is also a high load on the system components. For example, the sausage cutting machine will be used by the end user at least five days a week for three shifts at a time. It is cleaned once a day. All interior and exterior areas must therefore be able to withstand wet conditions and cleaning chemicals.

Solution

The machine manufacturer relies on maintenance-free and lubrication-free polymer plain and spherical bearings and linear technology in its entire range of machines and systems. They are economical, easy to install and harmonise with stainless steel:sausage cutting machine

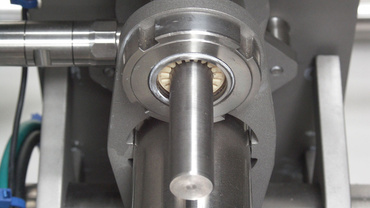

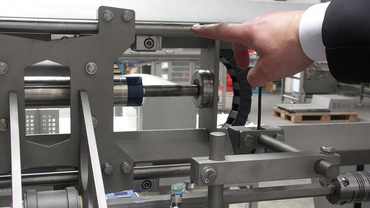

In the cutting machine, robust drylin linear guides and trapezoidal lead screws as well as corrosion-free igubal fixed flange bearings prove their versatility (see picture 1 and 2 below). They are designed for direct contact with food. While needle roller bearings used to leak during the cleaning process and often had to be replaced, polymer bearings have low total moisture absorption and are chemical resistant. In addition, durable polymer energy supply systems (picture 3) provide the necessary power supply.

Spreading mechanism

A drylin W single rail guide (picture 4) made of stainless steel with sliding elements made of iglidur J, which can be quickly installed, is used in the spreading mechanism of the sausage cutting machine.Knife edge deflections

In addition to insensitive linear guides with JUM liners, plain bearings made of iglidur P210 are used in the knife edge deflections (picture 5). They serve as anti-rotation feature and have a high thermal stability and low total moisture absorption.Transport systems

The transport systems from Singer & Sohn prove their worth not only in the meat industry but also sometimes in large bakeries where there is a lot of heat near the ovens. The plain bearing material P210 is now being used and improves the service life and run times for customers.

Bearing of the pivot cylinders

Cost-effective EFSM fixed flange bearings are also installed for the bearing of the pivot cylinders. Even the hatch of the control cabinet is equipped with a plastic plain bearing, which ensures that it opens and closes quietly (picture 6).

Dieter Koller, Head of Design