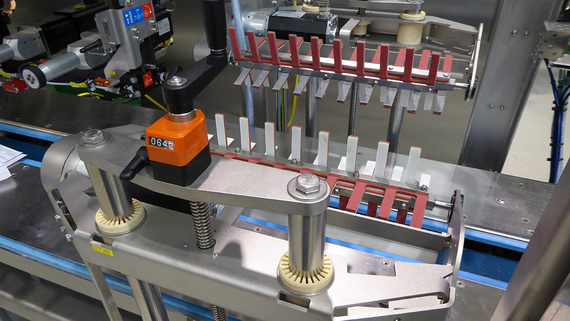

Labelling

Container transport module in labelling machines: Linear bearings and systems, nuts and plain bearing bushes are used in numerous substructure groups to adjust the modules to the different container sizes and formats. High hygienic requirements often need to be taken into account during these working processes, as for example in the beverage industry. Here aggressive cleaning is required and the machines need to be lubrication and corrosion-free. Even when the systems are polluted with glass splitters or PET fragments – they need to operate safely. The container transport module should be optimized for cost and hygienic reasons. Lightweight design and proven special construction had to be integrated. The advantages of plastic solutions in the individual modules: Freedom from lubrication, chemical resistance, lightweight design, dirt resistance, corrosion-free, cheap and uniform design. The elements could be simultaneously converted into sheet metal bending parts. It reduces both weight and stiffness.