Measuring system cables for large machining centers

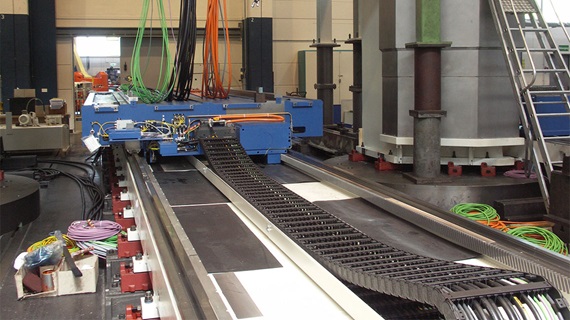

WALDRICH COBURG GmbH, a machine tool manufacturer, uses the latest generation of control systems for its highly complex systems.

Machining large components such as diesel engines, turbines, generators, and ships' propellers means bigger and bigger machining centres. This development is also having an impact on machine tool technology. The machine tool builder for these complex systems uses the latest generation of control systems. A special overall solution involving a measuring system cable that continuously transmits signals reliably over very long distances and ensures a high degree of machine availability has been developed for these systems.- What was needed: readychain system consisting of energy chain and chainflex cables such as the measuring system cable CF113.028.D, and M23 round connectors.

- Requirements: High availability of cable guides and cables under continuous load, partly harsh environmental condition in metalworking, overall high mechanical, electrical and chemical requirements

- Industry: Large machine tool construction

- Success for the customer: Individual connection solution adapted to the customer's system through a series of tests in the test laboratory, high durability and signal quality, extremely low attenuation properties.

Problem

WALDRICH COBURG GmbH is one of the world's leading mechanical engineering companies for large machine tools. Highest quality standards and consistent customer orientation are the machine builder's guiding principles. Horizontal and vertical milling machines and vertical lathes and grinding machines are produced at the Coburg production site.WALDRICH COBURG customers often use the machines for 20-30 years or longer with a necessary availability of at least 95%. So all components have to work flawlessly and continuously, whatever the circumstances. These demands mean a particularly high requirement profile for the application's cable guidance system.And the cables have to handle the continuous movement in energy chains and ambient metal machining conditions, which are sometimes tough, without suffering any damage. Says Thomas Bischoff, "Cables and connectors must be robust and meet the mechanical, electrical, and chemical requirements. It must also be easy to process them during production without additional special tools. And we wanted to use the familiar cable and connector material as much as possible in order to avoid problems during the changeover."

Solution

Energy chains and chainflex cables from igus have been in use in large machining centres for many years. In smaller models of the gantry machining centres, the company uses pre-assembled energy supply systems that are sold under the name readychain. One reason for the decision: The manufacturer's customers like to use the machines for many years longer than expected and demand consistently high availability. "For this reason, all the components have to work faultlessly for a very long time - whatever the circumstances", says the Group Leader, summarising the requirements. "In this respect we have had very good experience over the years with chainflex cables from igus. "In 2010 the large machining centre specialist decided to use new control technology in its machines, which also required new measuring system cables. Due to good experiences in the past, the choice fell on the chainflex cable CF113.028.D.

CF113.D cables have a PUR jacket. They have an improved cable and shield structure for a longer service life in energy chains. In addition to the absence of halogens and their flame-retarding qualities, they satisfy other important criteria of the machine tool manufacturer, including certifications according to UL and NFPA79.2012.

Dipl.-Ing. Thomas Bätz, Electrical Design Group Manager at WALDRICH COBURG GmbH

Diverse tests in advance

In order to be able to present a solution, it is important that a cable functions correctly and that the number and nature of the individual connecting points are appropriate. "This cannot be a standard ready-to-use solution from the catalogue", explains igus product manager, Andreas Muckes. "We looked into the matter in great detail before we found the right answer. " In the igus test laboratory in Cologne, series of tests were set up in order to find the best connection solution. The cables were then sent to the user, who connected them to an original control system. Realistic machine loads were simulated in order to test the finalised cable concept for its suitability for everyday use.All the efforts eventually led to the desired result. Today, the measuring system cables are showing what they can do in all machine centres with the new generation of control systems - even in cases where older machines have been retrofitted. They worked perfectly from the very beginning. A big advantage when it comes to assembly is that the popular M23 round connector can be used as standard components.

"The results are convincing. The durability and the signal quality meet the requirements. A total length of 90 to 100 m is possible at the moment without any problems but 120 m is also conceivable“, says Thomas Bätz. In addition, there is a maximum of five connection points. "With this combination of connector and cable, we achieve extremely low attenuation. It is many times lower than in the case of the original of the control system manufacturer", adds Thomas Bischoff.

Complete stocks

Measuring system cables are always harmonised with the associated measuring system from one of the various suppliers. They must function correctly for a long time. "Our robustness and stability requirements were fulfilled from the very beginning," reiterates Bischoff. "The prerequisite is good, close cooperation in the development process."WALDRICH COBURG exclusively uses a wide variety of chainflex cables in its own machining centres, guaranteeing long machine service life. The cables must also be available from stock. "There were no problems of any kind here, either," concludes Bätz. "There are no bottlenecks, so we can react quickly when necessary."