vector award

... for inspiring applications with e-chains® …e-chain systems® with cables…

Modern polymer energy supply chains are the umbilical cord of mechanical engineering and automation These energy chains ensure the safe supply of energy, data, pulses and operating media and are always in motion. They can be used universally – on cranes, machine tools and robots, all the way to Hollywood.Applications of contestants 2014 (PDF)

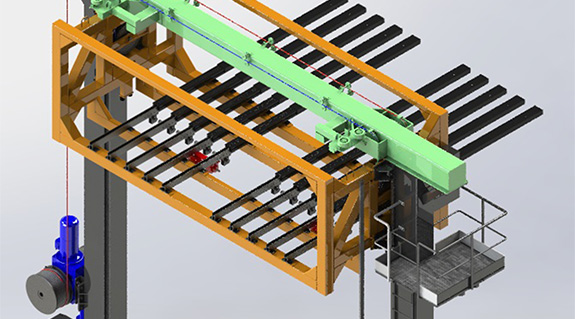

Cable robot

This cable robot is used in automated high-bay shelving systems.Cable robot

Wall bracket

This wall bracket allows the TV set to be swivelled through 120 degrees. Up to now, cables simply hung loosely and became tangled after several swivelling movements, causing the cables to break.Wall bracket

Labelling machine

This labelling machine takes labels from the stack, applies adhesive and then fixes the labels to the packaging.Labelling machine

Perfect guidance

The rotary collectors of this woodworking machine were extremely prone to malfunction in the past, and had to be renewed every six months due to damaged electric and hydraulic lines.Perfect guidance

Folding sliding blinds

These folding sliding blinds are motor-driven and thus automatically protect entire extensively glazed façades from sun radiation.Folding sliding blinds

Drilling and piling machines

These drilling and piling machines are used in railway construction, for example, to set concrete piles for electric cables.Drilling and piling machines

High frequency welding apparatus

This high-frequency welding apparatus moves in a working area of 8 x 2,5 metres and rotates about 360 degrees.High frequency welding apparatus

The system operates very silent now.

This patient positioning and imaging system is used in the radiotherapy.The system operates very silent now.

Edge-jointing unit

This machine connects a CNC machining centre with 5-axis technology to an edge-jointing unit, permitting new design options for furniture.Edge-jointing unit

Pontoon

The service boats of a wind farm operator are prepared for use at this pontoon in Barrow-in-Furness, Great Britain.Pontoon

Lifting system

The lifting system "Spiralift" is used in theatres and concert halls all over the world to raise and lower parts of the stage, for example.Lifting system

Tide turbine

Tide turbines generate electricity from fast-flowing water.Tide turbine

Transfer table

This transfer table in the English harbour town of Felixstowe ensures that railway engines are moved quickly to the correct one of eight tracks.Transfer table

Production machine

The production machine saws, mills and punches aluminium sheets.Production machine

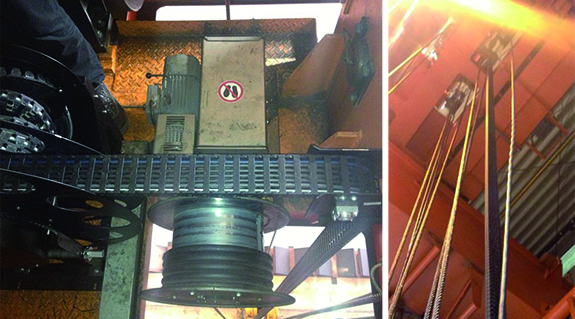

Coil crane

On this coil crane, the motor-driven cable drums required a lot of maintenance.Coil crane

Transporter

This vehicle was especially designed for the transport of windcraft wings.Transporter

Plasma cutting machine

This plasma cutting machine cuts metal plates at maximum speed.Plasma cutting machine

Automated warehouse

This warehouse is loaded automatically.Automated warehouse

Packaging machines

This packing machine automatically turns single bottles inside the packing into the desired position.Packaging machines

Robots

This robot moves very smooth.Robots

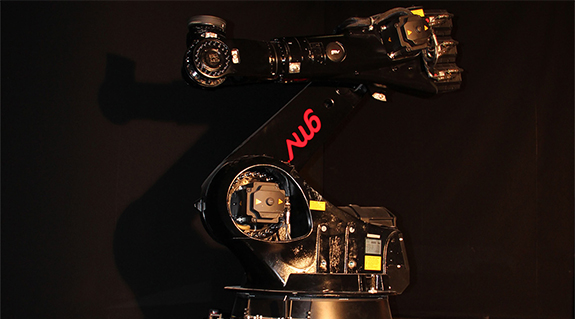

Robots

This robot is intended for space missions.Robots

Crane

This crane transports billets with the help of a magnet traverse in a steelwork.Crane

Galvanization facility

Six transport trolleys move material through the individual stations in this galvanization plant.Galvanization facility

Further Applications

vector_2014_further_applicants.pdf